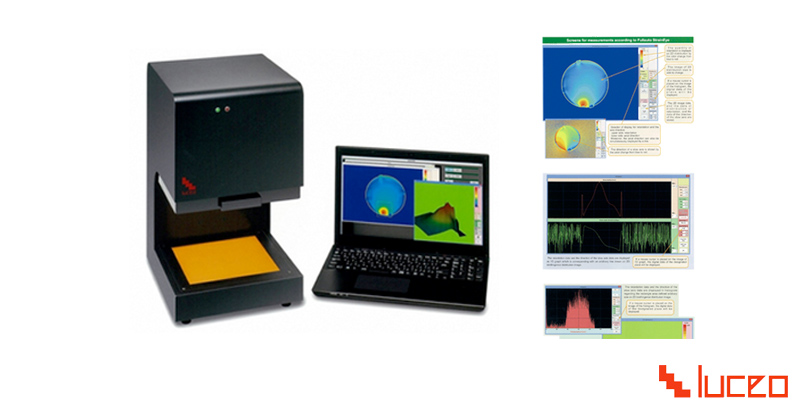

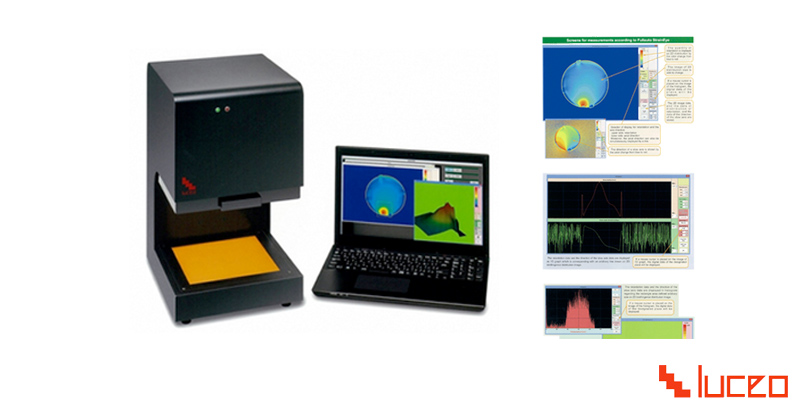

LSM-9000LE

-Full automatic type

-Quantitative measurement of residual stress in glassware

-Strain inspection for plastic products

-Phase difference measurement for optical film

-Strain Detection for crystalline material

Luceo | polarizing plate, wavelength plate, polariscope, polarimeter, optical sensor,glass surface stress meter

More about luceo

Luceo Co., Ltd. has been developed polarization technology for a long time, and now supplies a fully automatic polariscope as a strategy product, bringing original technology to the market.

StrainEye LSM-9000LE is a fully automatic 2D-measuring device which measures retardation values and the direction of a slow axis in a transparent body having strain and birefringence therein.

In order to measure direction and birefringence, conventionally the visual observation type of polariscope using the Senarmont method is used. As well, our in-house manufactured product, Semi automatic Senarmont which performs semi-automatic operations with the analyzer only manually rotated is also used.

The Senarmont method is an inspection method for measuring retardation quantitatively. An operator rotates the analyzer so that brightness of the object to be measured changes from the brightest state to darkest state, and measures its retardation by rotating the analyzer angularly. However, this conventional type has a problem such as the difference in decision of the brightness due to the difference in the condition during the measurement and also due to the difference in skill of each operator. Moreover, in Semi automatic Senalmont, although the accuracy of retardation measurement has improved from the visual observation type, the area to be measured is defined to the specific small portion in an image. Furthermore, in the Senalmont method, the direction of slow axis cannot be measured, and it only can be guessed, in consideration to the result of the sensitive color method. Moreover, when displaying 2D distribution is desired, many results measured and obtained much time is needed to map and measure the results.

This Full automatic StrainEye makes it possible to start measuring immediately by only putting a sample onto the polarizer. Therefore, retardation values and the direction of the slow axis can be measured easily. The measurement result is not influenced by each pixel of differences of personal skill. Not only a specific part is not subjected to the measurement but all of each pixel of a built-in CCD camera measures the entire detecting part. Since the direction of retardation and a slow axis are 2D-displayed on a monitor, those direction states are recognized immediately by the operator.

This device is connected with a PC, and it is therefore feasible to save not only the measured data but also the observed image data easily.

With the use of super-luminescent LED as a light source, this detector is designed for long life and low power consumption. Accordingly maintenance and replacement of the light source as well as running costs can be reduced or dispensed with all together.

The mechanism does not measure unless the shutter is down providing darkness.

Unnecessary light is eliminated and stable accuracy is obtained by this mechanism.

590nm wavelength of the light source is used.

The objects cannot be inspected, which this wavelength of light source is not transmitted.

Neither objects below this wavelength nor objects diffusing light can be accurately inspected.

| Size(body) | W280☓D340☓H500mm |

|---|---|

| Weight(body) | 15kg |

| Circulary polarizing plate size | W200☓D200mm |

| Sample placement space height | 0~130mm |

| Inspection Method | Rotating analyzer method |

| Setting Wavelength | 590mm |

| Repeat accrary(standard deviation) | σ=1nm |

| Measurement area size | 175☓175mm |

| Effective pixels | 1100☓1100 |

| Light Source | high-luminance LED |

| Power Source | AC100~240V 50/60Hz 0.35A |

| Component | Mainbody,PC,Cables |

| Accessory | Main body cover |

| OS | Windows7 (64bit) / Windows 8 (64bit) |

Get in contact with our friendly support staff.

We will be happy to assist you in all matters of your purchasing requirements and are looking forward to your inquiry.

All fields are required.

-Full automatic type

-Quantitative measurement of residual stress in glassware

-Strain inspection for plastic products

-Phase difference measurement for optical film

-Strain Detection for crystalline material

-Semi automatic type

-Quantitative measurement of residual stress of glassware

-Strain inspection of plastic products

-Phase difference measurement of the optical film

-Check whether there is any strain of crystalline material, etc.

-Handy type

-For the edge of sheet glass

-For small glass product

-For small plastic product

-Midium type

-For the edge of sheet glass

-For small glass product

-For small plastic product

-Midium type

-For the edge of sheet glass

-For small glass product

-For small plastic product

-Midium type

-For the edge of sheet glass

-For small glass product

-For small plastic product

-Midium type

-For the edge of sheet glass

-For small glass product

-For small plastic product

-Midium type

-For the edge of sheet glass

-For small glass product

-For small plastic product

-Measures glass thickness automatically by using the Glass Thickness Meter

-Measures the surface stress in wide angle using the Wide Angle Camera

-Output of measured data

-Renewal

-Built-in Camera

-No Battery USB powered

-Improvement of stability